The concept of 3D printing—creating three-dimensional objects by depositing consecutive layers of material—has evolved from a novelty to a critical manufacturing technology. When you ask, "How does a 3D printer work?" the answer lies in understanding Additive Manufacturing (AM), the family of technologies that builds an object layer by layer, in direct contrast to traditional methods that cut material away.

This comprehensive guide explores the core technologies, the step-by-step process, and the wide-ranging applications of 3D printing, from its history in Rapid Prototyping (RP) to its current role in aerospace, medicine, and home use.

History and Fundamentals of Additive Manufacturing (AM)

The earliest form of AM began in the late 1980s and early 1990s as Rapid Prototyping (RP). RP allowed manufacturers to quickly create physical prototypes from Computer-Aided Design (CAD) software models, drastically speeding up the design and testing phases. Early leaders like MIT (which trademarked the 3DP process) and 3D Systems (pioneering Stereolithography Apparatus, SLA and Selective Laser Sintering, SLS) established the foundational techniques that define modern 3D printing.

AM vs. Subtractive Manufacturing

It is important to distinguish AM from its counterpart, Subtractive Manufacturing (e.g., CNC machining). Subtractive methods remove material from a solid block until the finished product remains (like carving wood). AM, conversely, adds material only where needed, layer by layer, which often leads to less material waste and the ability to create complex internal geometries impossible with carving or molding.

Core 3D Printing Technologies

The specific method a printer uses to bind and cure the material defines its technology. Here are four widely adopted AM technologies:

1. Direct and Binder 3D Printing

- Direct 3D Printing (Similar to FDM/MJM): This approach utilizes inkjet technology. Instead of ink, nozzles dispense thick waxes or plastic polymers that solidify instantly. The printing platform or the nozzle moves vertically to accommodate subsequent layers. Fused Deposition Modeling (FDM), trademarked by Stratasys, is a well-known example that injects molten plastic in fine, closely packed lines.

- Binder 3D Printing (MIT's 3DP): This method uses two materials: a fine dry powder and a liquid glue (binder). The machine makes two passes for each layer: first spreading the powder, then applying the binder via nozzles to solidify the cross-section. This is generally faster than Direct Printing and allows for a wider range of materials, including colored materials, ceramics, and metals.

![[Diagram illustrating 3D binder printing process]](https://media.hswstatic.com/eyJidWNrZXQiOiJjb250ZW50Lmhzd3N0YXRpYy5jb20iLCJrZXkiOiJnaWZcLzMtZC1wcmludGluZy0yLmdpZiIsImVkaXRzIjp7InJlc2l6ZSI6eyJ3aWR0aCI6MjkwfX19)

2. Photopolymerization (SLA)

Photopolymerization involves using light to convert a liquid plastic into a solid. The most common form is Stereolithography Apparatus (SLA):

- Process: A vat is filled with liquid plastic known as photopolymer. A precisely aimed ultraviolet (UV) laser is directed across the surface, tracing the cross-section of the object.

- Curing: The UV light instantly cures (solidifies) the liquid plastic wherever the laser hits it. The platform then lowers slightly, and the process repeats until the object is complete.

3. Sintering (SLS)

Sintering is an AM technology that relies on heat to melt and fuse powdered materials together:

- Selective Laser Sintering (SLS): A powerful UV laser beam melts a bed of fine powdered material (which can be plastic, ceramic, or metal). The melted powder then solidifies to form the layer.

- Metal Manufacturing: SLS is highly compatible with building metal objects, offering high levels of precision that are difficult to achieve with traditional methods like die-casting.

![[Diagram illustrating Selective Laser Sintering process]](https://media.hswstatic.com/eyJidWNrZXQiOiJjb250ZW50Lmhzd3N0YXRpYy5jb20iLCJrZXkiOiJnaWZcLzMtZC1wcmludGluZy0zLmdpZiIsImVkaXRzIjp7InJlc2l6ZSI6eyJ3aWR0aCI6MjkwfX19)

The 8-Step Generic 3D Printing Process

Regardless of the specific AM technology used, the overall workflow from design to finished object follows a standardized sequence:

- CAD: Create a 3D model using Computer-Aided Design (CAD) software.

- Conversion to STL: Convert the CAD model into the STL (Standard Tessellation Language) file format. STL files define the geometry of the object using triangular facets and are universally used by 3D printers.

- Transfer and Manipulation: Copy the STL file to the printer's controlling computer. Users designate the print size and orientation for optimal printing.

- Machine Setup: Prepare the printer by ensuring consumables (polymers, powders, binders) are full and that any required temporary water-soluble support materials are ready.

- Build: The mostly automatic process begins. The machine builds the object layer by layer (typically around 0.1 mm thick). This step can take hours or days depending on object size and complexity.

- Removal: Carefully remove the finished object from the machine, observing all safety protocols (gloves for heat or chemicals).

- Post-processing: The printed object often requires cleanup. This may involve brushing off excess powder, bathing the part to dissolve supports, or allowing the material time to cure and reach full strength.

- Application: The final object is ready for use, testing, or sale.

Widespread Applications and Controversies

Revolutionizing Industries 🚀

3D printing has moved far beyond just prototyping, making significant contributions across multiple sectors:

- Medical: Used extensively for printing prosthetics (often at a fraction of the cost of traditional methods), creating realistic surgical models for planning facial reconstruction, and for specialized dental applications.

- Aerospace: Used for designing and testing parts, with ambitious goals to manufacture complex, lightweight aircraft components (like entire wings) to improve fuel efficiency.

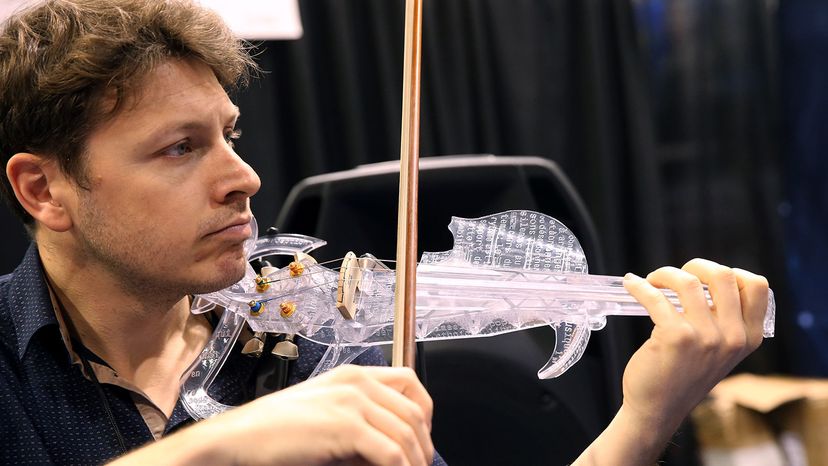

- Art & Design: Used by artists and designers to produce intricate furniture, specialized lighting, and complex geometric sculptures.

- Culinary: Used to create customized food items, such as unique chocolate confections or even pureed food items like customized burgers.

Drawbacks and Controversial Issues ⚖️

Despite its promise, 3D printing faces technological and legal challenges:

- Environmental and Health Concerns: AM processes often use significant electrical energy (up to 100 times more than standard manufacturing) and can emit carcinogenic particles and volatile organic compounds (VOCs), especially in enclosed spaces.

- Waste: The plastic remnants from many projects often end up contributing to plastic waste in landfills.

- Illicit Manufacturing: The technology allows individuals to produce items like guns, knives, and other weapons, raising serious public safety and regulatory concerns.

- Intellectual Property (IP): It is challenging for patent or copyright holders to track down individuals who print patented objects from readily available blueprints, making IP violation enforcement difficult.

3D Printing at Home and Service Options

As the technology matures, home use becomes more feasible. Prices for consumer-grade FDM printers are dropping, making them accessible for schools, libraries, and makerspaces. For example, some models now start around $1,375 (as of 2024), with various filament materials (like PLA) available for purchase.

If you don't wish to invest in your own machine, specialized online services (like Shapeways or Ponoko) allow you to send your CAD/STL file to be printed on industrial-grade 3D printers, guaranteeing high quality and materials (including metals and ceramics) beyond the scope of home units.

Frequently Asked Questions (FAQ) 😊

Quick answers to common questions about 3D printing! :D

Q: What is the main difference between 3D printing and CNC machining?

3D printing uses Additive Manufacturing (AM), meaning it builds an object by adding material layer by layer. CNC machining uses Subtractive Manufacturing, meaning it removes or carves material from a large pre-existing block until the desired shape remains.

Q: Why do I need to convert my CAD file to STL format?

The STL (Standard Tessellation Language) file format is the universal standard for 3D printing. It represents the surface geometry of the 3D model using tiny triangular facets. This simple geometric representation is what the printer's software uses to slice the object into printable layers (cross-sections).

Q: What is the main safety concern when running a 3D printer at home?

A major concern is the emission of carcinogenic particles and volatile organic compounds (VOCs), particularly when using common plastic filaments in small, unventilated spaces. Proper ventilation is crucial for minimizing this health risk.